A Comprehensive Overview of Plate Heat Exchangers

2024-02-24 | Heat Exchanger

Plate heat exchangers (PHEs) have revolutionized heat transfer in various industries, offering unparalleled efficiency and versatility. In this blog post, we will delve into the intricacies of plate heat exchangers, exploring their design, working principles, and applications. From stainless steel construction to high heat transfer capabilities, we will cover all the essential aspects that make plate heat exchangers indispensable in modern engineering.

Understanding Plate Heat Exchangers:

Plate and frame heat exchangers form the backbone of efficient heat transfer systems. Comprising corrugated plates, these exchangers create a series of channels for hot and cold fluids to flow. The corrugation enhances turbulence, promoting high heat transfer rates. This design is instrumental in achieving optimal performance while minimizing pressure drop.

Materials Matter - Stainless Steel and Beyond:

One key feature setting plate heat exchangers apart is their construction material. The use of stainless steel ensures durability, corrosion resistance, and suitability for a wide range of applications. Gasketed plate heat exchangers, in particular, employ elastomer gaskets to seal the plates, allowing for easy maintenance and flexibility in handling different fluids. Meanwhile, brazed plate heat exchangers use a braze material, typically copper, to join the plates, ensuring a robust and compact design.

Types of Plate Heat Exchangers:

Plate heat exchangers come in various types to cater to diverse needs. Gasketed plate heat exchangers, with their easily replaceable gaskets, are suitable for applications where flexibility is paramount. On the other hand, brazed plate heat exchangers, with their compact design and high heat transfer efficiency, are ideal for applications demanding a smaller footprint.

Comparing with Shell and Tube Heat Exchangers:

Plate heat exchangers are often compared with traditional shell and tube heat exchangers. While the latter has its merits, PHEs excel in terms of efficiency, compactness, and adaptability. The plate pack design ensures a larger surface area for heat exchange, leading to improved performance with lower flow rates and reduced pressure drop.

Operating at High Pressure and Temperature:

One of the remarkable attributes of plate heat exchangers is their capability to operate at high pressure and temperature. This makes them suitable for applications where demanding conditions are prevalent, such as in industrial processes where heat transfer efficiency is critical.

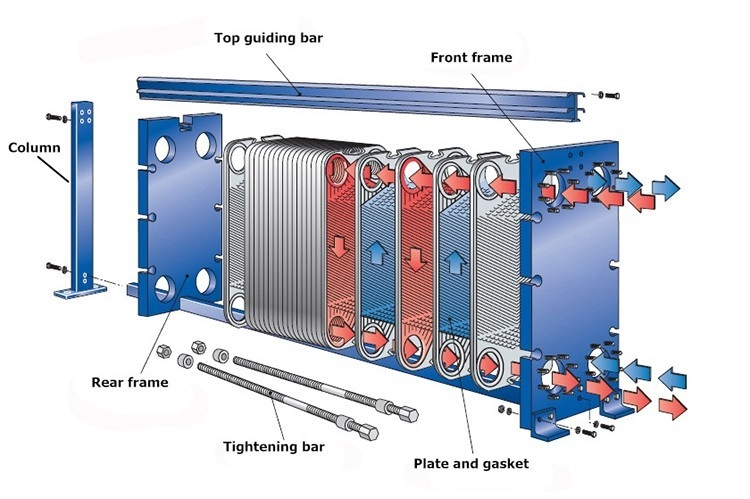

Carrying Bars and Plate Packs:

The plate pack, consisting of multiple plates stacked together, is a fundamental component of plate heat exchangers. Carrying bars support the plates and facilitate their alignment within the frame, ensuring uniform distribution of fluids across the heat exchanger. This structural design enhances the overall stability and longevity of the system.

Conclusion

Plate heat exchangers stand as a testament to innovation in heat transfer technology. Their versatility, efficiency, and adaptability make them indispensable in various industries. From gasketed plate heat exchangers to brazed plate variants, the choice depends on the specific requirements of the application. With stainless steel construction, high heat transfer capabilities, and the ability to operate under high pressure and temperature conditions, plate heat exchangers continue to play a crucial role in shaping the future of efficient heat exchange systems.