Design temperature: -195~500℃ (standard design -80~300℃, others as required.)

Design pressure: vacuum ~ 7.0Mpa (standard design 1, 6, 10, 16, 25, 40bar, others as required)

Veneer area: 0.016~2.0㎡

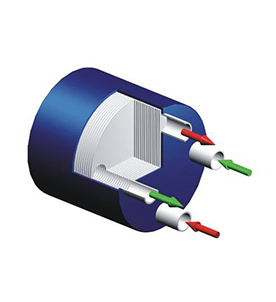

The plates and welding technology of Polytech plate and shell heat exchangers originate from Denmark. It is a heat exchanger that uses a laser-welded corrugated plate group as a heat transfer element and combines with the shell to form two different medium flow channels. It is also called a lamella heat exchanger. It combines the advantages of plate and tube heat exchangers and is widely used in the field of heat transfer. The corrugated plates are made of stainless steel and have excellent corrosion resistance. Fluid A flows between the plates, and fluid B flows between the plates in the shell. When the fluid flows through the corrugated plates, it can generate high turbulence in the counter-flow direction. The heat exchange efficiency is greatly improved. The plate and shell heat exchanger adopts a compact plate structure, is small in size, easy to maintain, and saves materials. Its high heat transfer coefficient makes it highly cost-effective, ensuring performance and bringing more work benefits.

★Compact structure, small size, easier for maintenance and service

★Unique herringbone corrugated design with extremely high thermal conductivity

★Low volume, small resistance loss and small heat loss

★Laser or plasma welding, better sealing

★Wide operating pressure, up to 70bar

★The heat exchange area can be freely expanded or reduced according to the actual load

★Excellent material plate (AISI304/316L), stronger corrosion resistance

General machinery supporting applications

Polytech plate and shell heat exchangers are high-performance, multi-purpose and are used for heating, cooling, evaporation, condensation and heat recovery of any liquid and gas. Its corrugated sheets and compact construction resist severe thermal shock and pressure fluctuations.

It is widely used in traditional light industrial machinery and general industry, and is used in batches as a complete set of equipment.

Refrigeration industry applications

Polytech plate and shell heat exchangers can be used as evaporators, condensers, condensing evaporators, superheated steam coolers, oil coolers, etc., bringing many benefits to advanced refrigeration applications. Polytech plate and shell heat exchangers are efficient, durable and versatile. It is compact and requires only a small refrigerant charge. It is suitable for all refrigerants, especially the natural refrigerants ammonia and carbon dioxide.

Energy and marine applications

Polytech plate and shell heat exchangers are more compact than traditional shell and tube heat exchangers. It has a wide temperature operating range and pressure operating range, which can effectively resist thermal shock and pressure shock; at the same time, its fully welded structure without sealing gasket makes it basically free of any maintenance costs. Plate and shell heat exchangers are therefore suitable for many applications in the energy technology and shipbuilding industries.

Chemical and petrochemical applications

Polytech plate and shell heat exchangers combine the advantages of traditional plate and shell heat exchangers and can be widely used and qualified for all application positions of traditional shell and tube heat exchanger equipment. It has the high temperature resistance and high pressure resistance of a shell and tube heat exchanger; its fully welded and gasket-less structure has wide applicability to process media; when precious metal materials are specified to be used, its high efficiency and compactness mean that precious metal materials effective utilization and cost savings.

Pharmaceutical and food industry applications

Polytech plate and shell heat exchangers are suitable for liquid-liquid, vapor-liquid, gas-liquid, gas-gas and other heat exchange processes. They can also be used as condensers, evaporators, etc. The unique wide flow channel design is especially suitable for heating and cooling process requirements of process media containing a large amount of solid particles and fiber suspensions.

▲Legs ▲Tank

▲Flange ▲Lifting ring

▲Grounding lug ▲Finishing processing

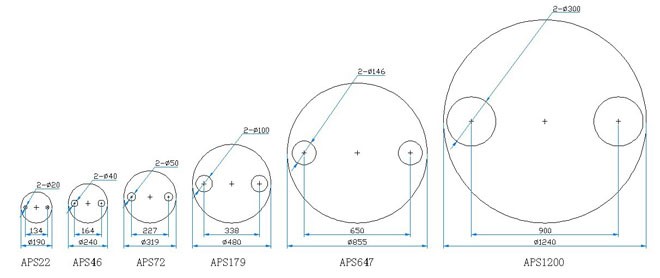

Model standard:

APS16, APS22, APS46, APS72, APS128, APS179, APS647, APS1200, APS1600