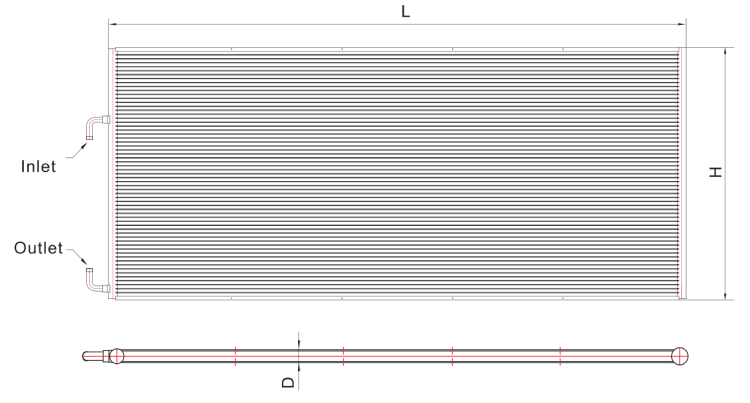

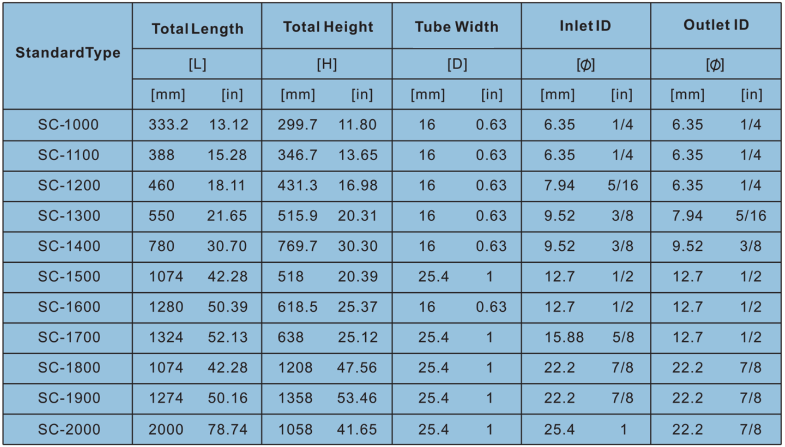

Microchannels are extremely small flow passages, typically referring to channel structures within the micrometer-scale range. These microchannels can be straight, curved, or have various shapes and geometries, but their defining characteristic is their very small size, typically ranging from micrometers (millionths of a meter) to millimeters (thousandths of a meter).

Microchannel technology finds extensive applications in the fields of science, engineering, and technology, particularly in areas such as microfluidics, heat transfer, biomedicine, and chemical reactions. Due to their high surface area-to-volume ratio, microchannels increase the contact area between fluid and solid surfaces, enabling higher efficiency in processes involving heat transfer, mass transfer, and reactions.

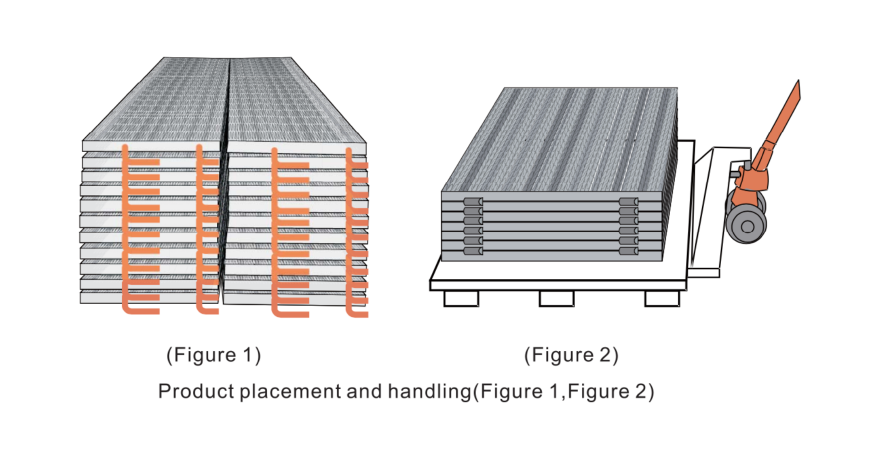

Product handlingThe product needs to be carefully handled to avoid collision due to the full aluminum structure of its main body Products shall be placed on a fit-size tray for a long distance carrying, which shall be separated by the cardboard or cushion pad between every 2 items and the bottom of downmost product. And then carried by forklift( Figure 2 Header tube and side plate are the bearing position that can be applied for proper lifting and handling.

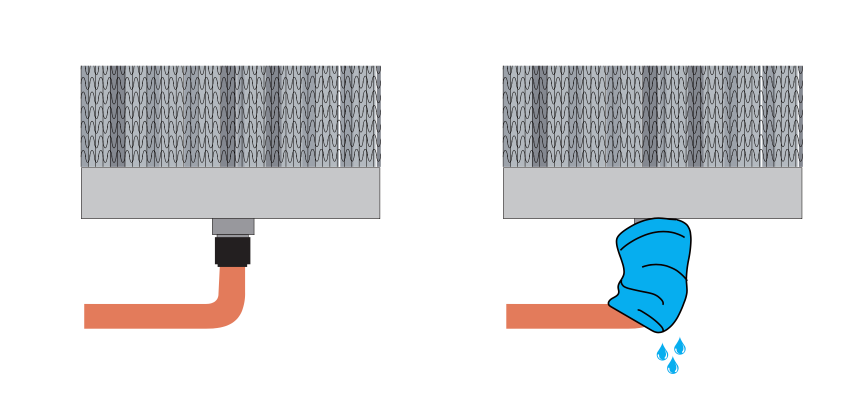

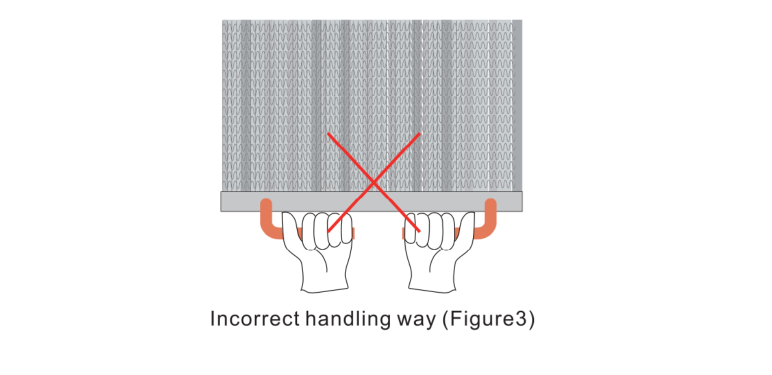

Directly holding the inlet & outlet pipe for handling is strictly forbidden, which could be very likely to result in the severe damage of pipe welding spot(Figure 3)

Product assembly

1.Since the damage of load bearing part may leads to the product malfunction, installation condition needs to be evaluated on spot to avoid any collision.

2.Directly pulling back the connecting pipe(Figure 4) is strictly forbidden when any deviation appears. The deviation can be revised by adding a proper connecting pipe.(Figure 5).

3.Checking the tightness of bolt, slot and buckle after the product is installed in the right position.

Product connection

1.The connecting ways of product usually include copper pipe welding, flange joint connecting and thread joint connecting. welding protection(Figure 6)

2.The safe welding temperature for our product is 400 degrees, welding point is likely to get failed if temperature exceeds the sate range. Please ensure that the distance from the welding point shall be more than 80mm when clients take welding by himself and the temperature is over 850 degrees. Meanwhile, please use wet cloth (With no drop of water appropriate) to provide protection for heat shrinkable tube and Copper-Aluminum welding point (Figure 6).