How does Combined Plate Heat Exchanger work?

2023-08-17 | Heat Exchanger

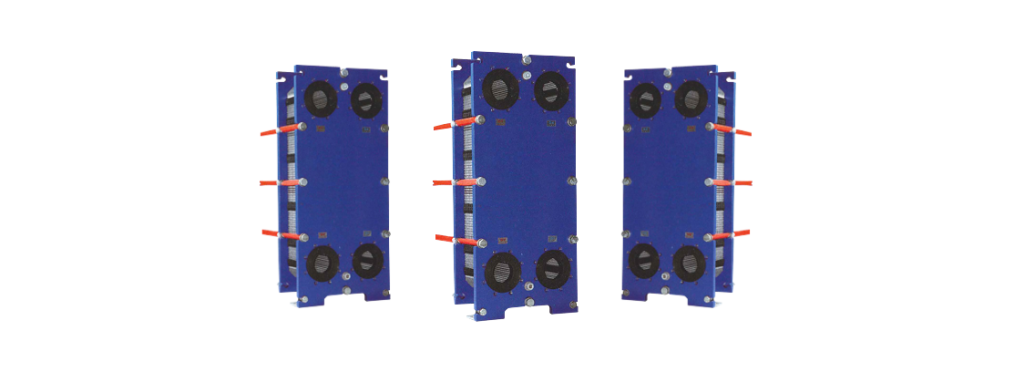

In the realm of heat exchange technology, innovation continues to drive efficiency and effectiveness. One such advancement is the combined plate heat exchanger, a marvel that optimizes heat transfer processes. In this blog, we will unravel the inner workings of a combined plate heat exchanger, shedding light on its operation in simple terms.

Understanding the Basics

A plate heat exchanger is a device designed to transfer heat between two fluids, without them coming into direct contact. The combined plate heat exchanger takes this concept to the next level by incorporating multiple sections, each with distinct fluids and specific heat transfer duties.

How It Works

1. Fluid Circulation:

The heat exchanger contains multiple plates, which create alternating channels for the two fluids. These channels allow the fluids to flow in close proximity to each other without mixing.

2. Parallel Flow:

The combined plate heat exchanger operates on a parallel flow arrangement. This means that both fluids enter the exchanger from the same side and move in the same direction. This maximizes the temperature difference between the fluids, enhancing heat transfer efficiency.

3. Counterflow Arrangement:

In some configurations, the heat exchanger employs a counterflow arrangement, where one fluid flows in the opposite direction to the other. This allows for efficient heat exchange as the fluids pass each other.

4. Heat Transfer:

As the hot fluid flows through its designated channels and the cold fluid flows through its own, heat is exchanged through the plates that separate them. This transfer occurs due to the temperature difference between the fluids.

Benefits of Combined Plate Heat Exchangers

1. High Efficiency:

The parallel flow and counterflow arrangements maximize the potential for efficient heat transfer, making combined plate heat exchangers highly effective.

2. Compact Design:

The stacked plate configuration results in a compact and space-saving design, making them suitable for applications with limited space.

3. Flexibility:

Different sections of the exchanger can handle various fluids and heat transfer duties, offering versatility for diverse applications.

4. Reduced Fouling:

The smooth plates and efficient flow patterns help minimize fouling, which can impede heat exchange efficiency.

Applications

Combined plate heat exchangers find applications in various industries, including HVAC systems, chemical processing, power plants, and food and beverage production. Their ability to efficiently transfer heat between fluids of varying temperatures makes them indispensable in optimizing processes.

Conclusion

The combined plate heat exchanger is a prime example of how innovation enhances the efficiency of heat exchange. By allowing multiple fluids to interact efficiently while maintaining separation, these devices play a crucial role in a wide range of industries. Understanding their operation provides insights into their value and potential applications.

Stay tuned to our blog for more in-depth explorations of heat exchange technologies and their real-world applications. To learn more about the intricacies of combined plate heat exchangers and to stay updated on the latest advancements, follow our blog and join the conversation.