Most Comprehensive Introduction to Heat Exchangers

2023-07-19 | Heat Exchanger

Heat exchangers are essential devices used in various industries to transfer heat between fluids while keeping them separate. Understanding their working principles and applications is crucial for grasping their significance in thermal management. In this blog, we will explore the fundamentals of heat exchangers, how they work, and their wide-ranging applications.

A heat exchanger is a device designed to transfer thermal energy between two or more fluids without mixing them. Fluids can be either liquids or gases. A heat exchanger helps transfer heat from a hot fluid to a cold fluid. This transfer can be used for heating, cooling, or both purposes.

Working Principles of Heat Exchangers:

Heat exchangers operate based on the principle of heat transfer through conduction. The process fluid, the hot fluid, flows through one set of tubes or channels. The cooling fluid, the cold fluid, flows through another set of tubes or channels. As the fluids come into contact, heat is transferred from the process fluid to the cooling fluid without mixing them.

According to the structural form and heat transfer mode, heat exchangers can be classified into the following types:

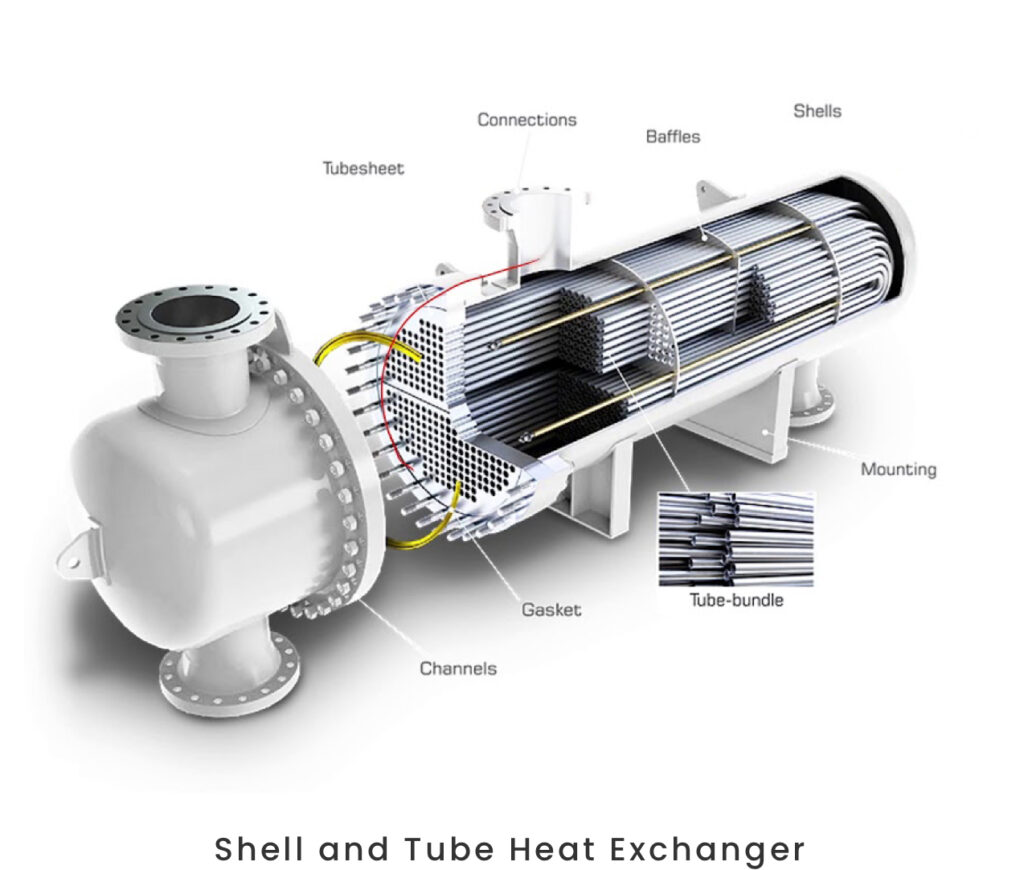

1.Shell and Tube Heat Exchanger:

This type consists of a shell (a large outer vessel) with a bundle of tubes inside. One fluid circulates through the tubes. This is known as the tube-side.

The other fluid flows over the tubes and into the shell. This is the shell-side. Heat is transferred through the tube walls, allowing efficient heat exchange between the two fluids. Shell and tube heat exchangers are versatile, widely used, and can handle high-pressure and high-temperature applications.

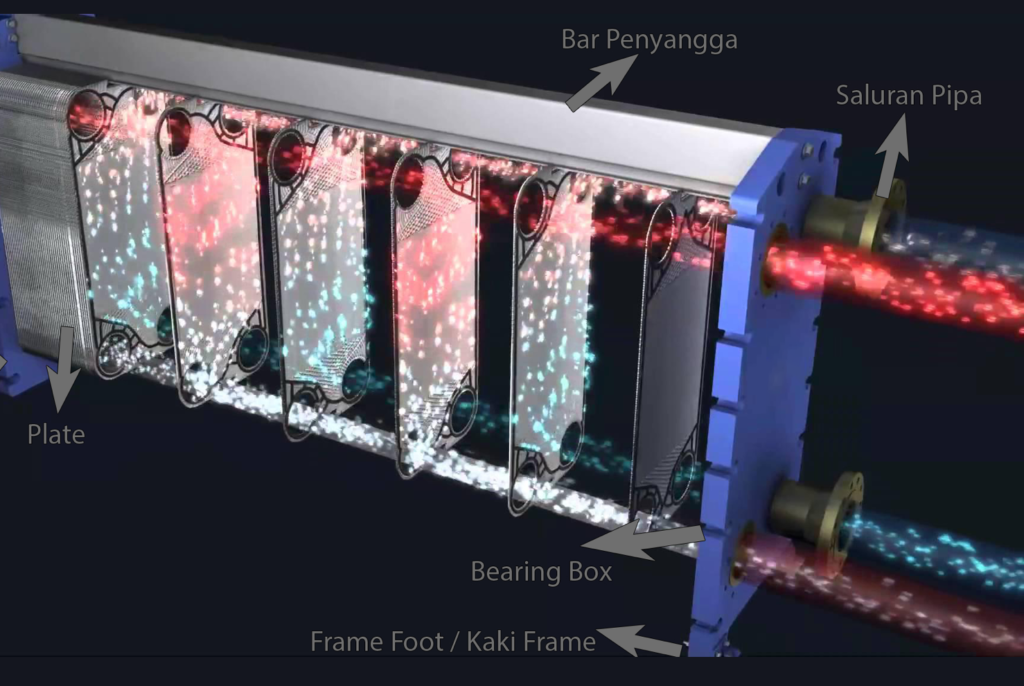

2. Plate Heat Exchanger:

Plate heat exchangers use a series of plates with alternating hot and cold fluid channels. The plates create a large surface area for heat transfer between the fluids. The hot and cold fluids flow in separate channels, with thin plates facilitating efficient heat exchange. Plate heat exchangers are compact, have high heat transfer efficiency, and are suitable for applications with low viscosity fluids.

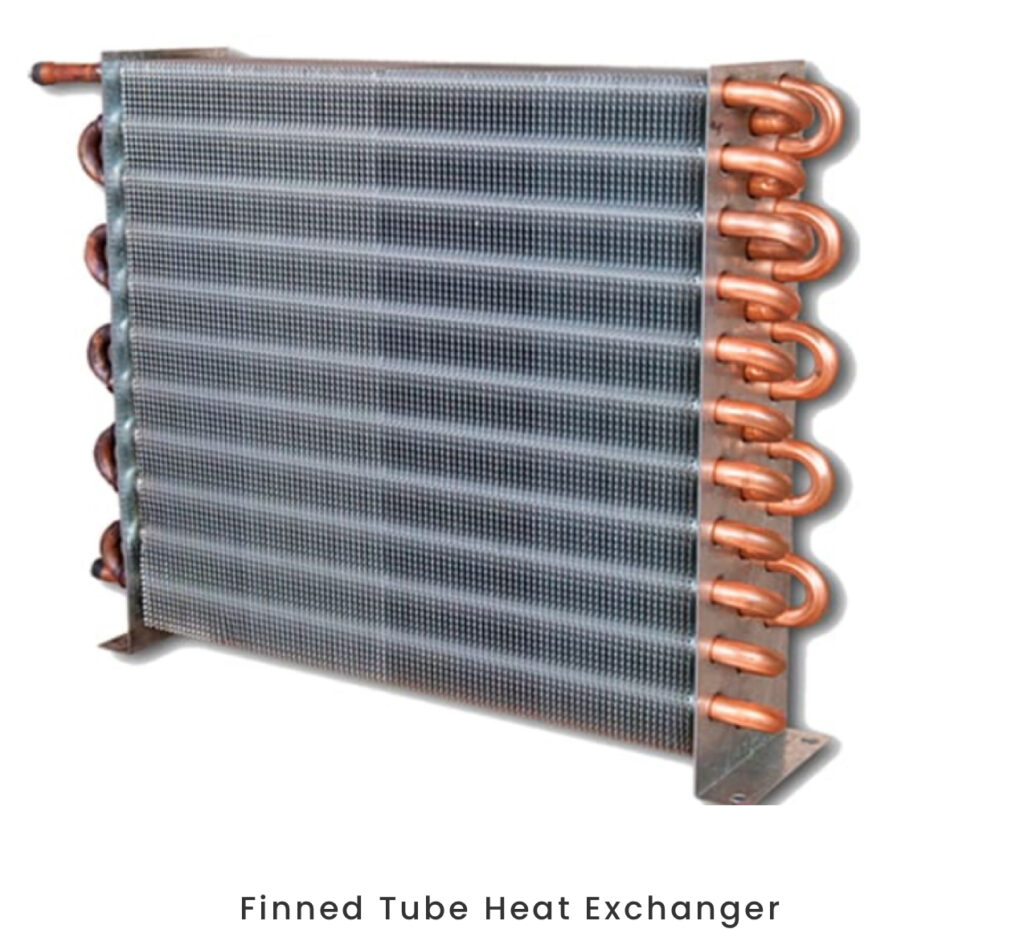

3. Finned Tube Heat Exchanger:

In a finned tube heat exchanger, extended surfaces (fins) are attached to the outer surface of the tubes. The fins increase the heat transfer area and enhance heat exchange efficiency. This type is commonly used when one fluid has a significantly higher heat transfer coefficient than the other. Finned tube heat exchangers are often used in air-cooling applications.

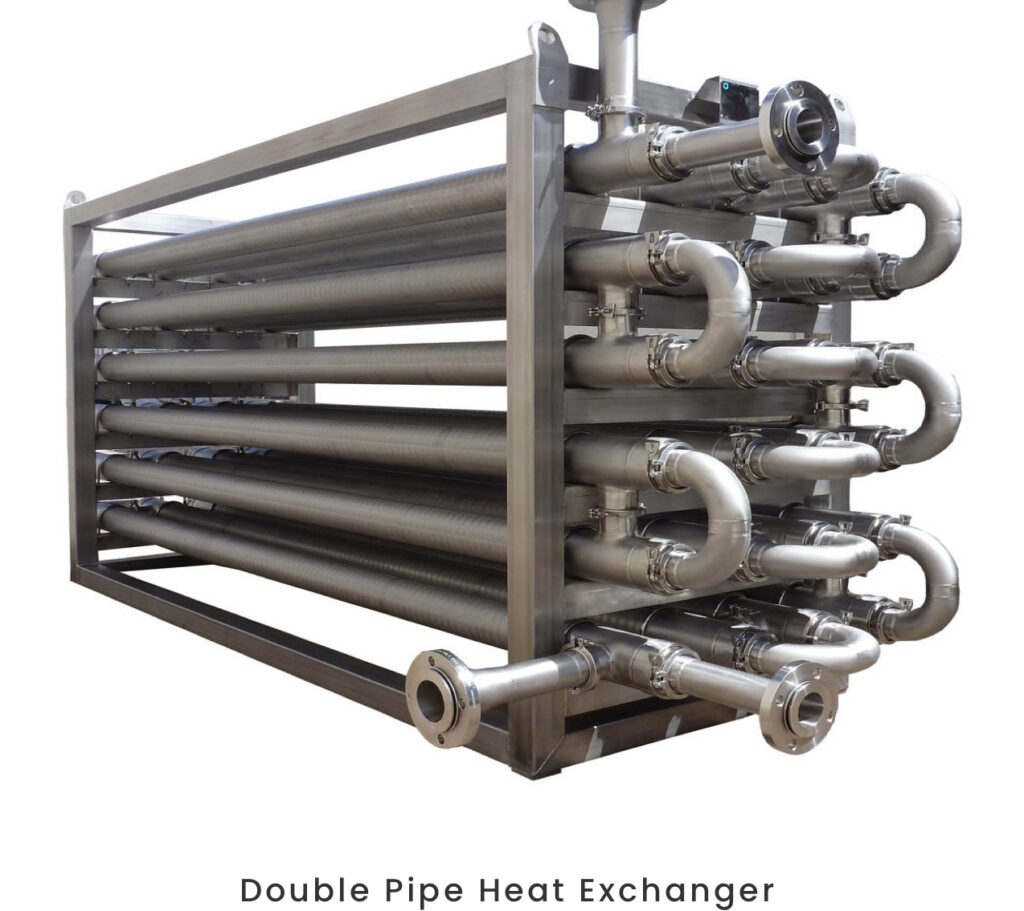

4. Double Pipe Heat Exchanger:

As the name suggests, a double pipe heat exchanger consists of two pipes, one inside the other. The hot and cold fluids flow through the inner and outer pipes, respectively. This design allows for a simple and compact heat exchanger, suitable for low-pressure and low-temperature applications. Double pipe heat exchangers are commonly used when space is limited or when handling corrosive fluids.

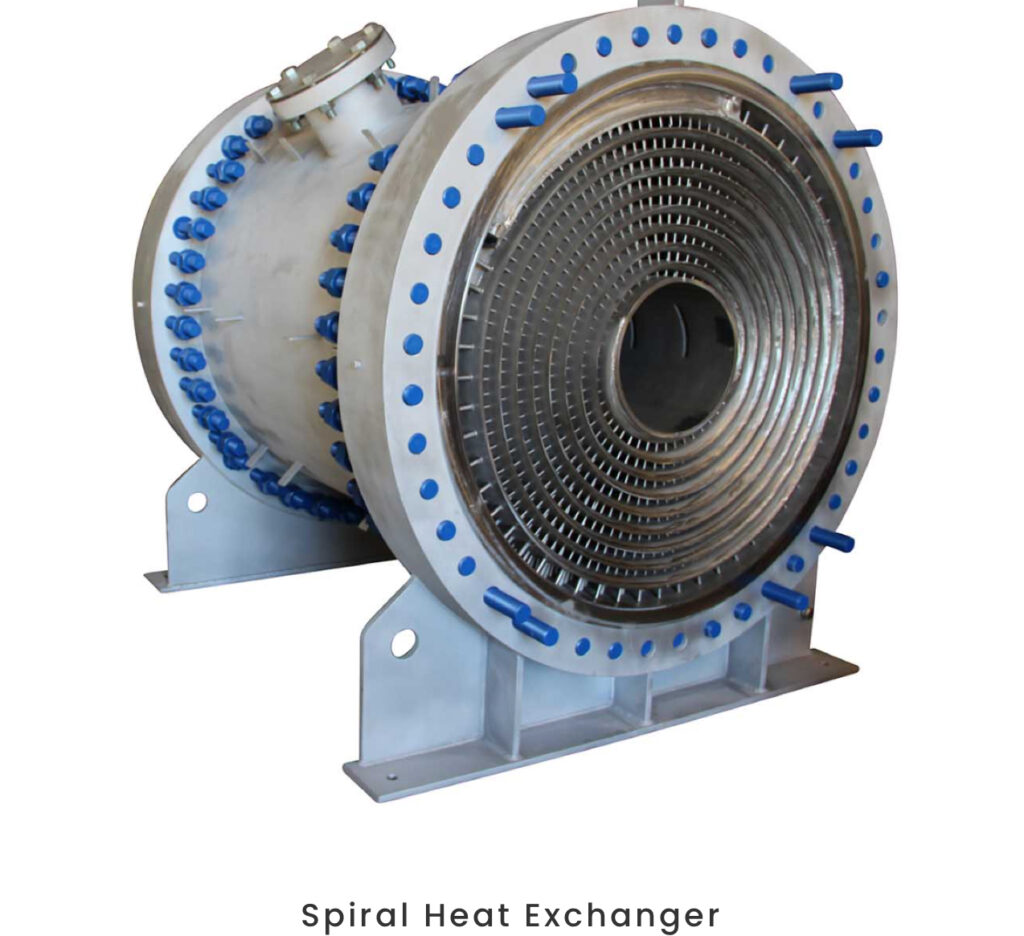

5. Spiral Heat Exchanger:

Spiral heat exchangers have two spiral channels, one within the other, which creates a counter-flow arrangement. The hot and cold fluids flow in opposite directions, providing efficient heat transfer. Spiral heat exchangers have a compact design and high heat transfer efficiency. They are suitable for applications involving viscous fluids or those with a high fouling tendency.

Types of Heat Exchangers based on Flow Configurations:

Heat exchangers can be classified into three main types based on their flow configurations:

1.Parallel-Flow Heat Exchangers: The process fluid and cooling fluid both flow in the same direction in this configuration. They enter the exchanger from one end and exit at the other end. This design allows for efficient heat transfer but may result in a smaller temperature difference between the fluids at the outlet.

2.Counterflow Heat Exchangers: In a counterflow arrangement, the process fluid and cooling fluid flow in opposite directions. This setup maximizes the temperature difference between the fluids, resulting in a more efficient heat transfer process.

3.Cross-Flow Heat Exchangers: Cross-flow heat exchangers feature fluid streams that flow perpendicular to each other. One fluid passes through the tubes, while the other flows across the tube surfaces. This design is frequently employed for heat transfer over a large area. Examples include air conditioning systems and radiator units.

Applications of Heat Exchangers:

Heat exchangers find applications across a wide range of industries and processes. Here are a few notable examples:

1. HVAC Systems:

Heat exchangers are integral components of heating, ventilation, and air conditioning (HVAC) systems. They facilitate efficient heat transfer between the air and a fluid, such as water or refrigerant. This enables effective heating or cooling of indoor spaces.

2. Power Generation:

Heat exchangers are extensively used in power plants. They extract and transfer heat generated by the combustion of fuels such as coal, natural gas, or through nuclear reactions. Heat exchangers are critical in systems like boilers, condensers, and steam generators.

3. Automotive Industry:

The automotive industry relies on heat exchangers to maintain optimal operating temperatures in vehicles. Examples of heat exchangers in vehicles include radiators and oil coolers. Engines and other components need to remain at the right temperature for smooth operation.

4. Chemical Processes:

Heat exchangers play a crucial role in chemical processing plants. They facilitate heat transfer in various stages of reactions, such as distillation, evaporation, and condensation.

5.Refrigeration and Air Conditioning:

Heat exchangers are employed in refrigeration and air conditioning systems. They transfer heat between the refrigerant and the ambient air, resulting in cooling effects.

Conclusion:

Heat exchangers are versatile devices that enable efficient heat transfer between fluids, making them vital components in numerous industries. Their ability to heat, cool, and control temperature has a major effect on energy efficiency, process optimization, and system performance.

It helps to reduce energy costs and improve system performance. It also optimizes processes and improves overall system performance.

We can understand the principles and applications of heat exchangers. This helps us to appreciate their importance in thermal management.

PULITE Co., Ltd. is committed to delivering superior heat exchangers. We also offer customized solutions to satisfy the individual needs of different industries. For more information, feel free to contact us at pulite@m168.com.tw.