What is Plate Heat Exchanger | Principles and Design of Plate Heat Exchanger

2023-10-24 | Heat Exchanger

What is Plate Heat Exchanger?

A plate heat exchanger (PHE) is a device that transfers heat between two fluids using metal plates. Compared to traditional heat exchangers, plate heat exchangers have a significant advantage: the fluids are exposed to a larger surface area as they are dispersed across the plates. This facilitates heat transfer and greatly accelerates the rate of temperature change. Plate heat exchangers are widely used today; very small welded versions are used in the hot water section of millions of combination boilers. Despite their small physical size, they have remarkably high heat transfer efficiency, enhancing the domestic hot water flow rate of combination boilers. Small plate heat exchangers have made a significant impact on home heating and hot water production. Larger commercial versions use gaskets between the plates, while smaller versions tend to be welded.

The concept of a heat exchanger involves heating or cooling a fluid through pipes or other vessels by transferring heat between it and another fluid. In most cases, the heat exchanger consists of a coiled pipe containing one fluid and a chamber containing another fluid. The walls of the pipe are typically made of metal or another highly thermally conductive material to facilitate heat exchange, while the outer casing of the larger chamber is made of plastic or covered with insulation material to prevent heat loss.

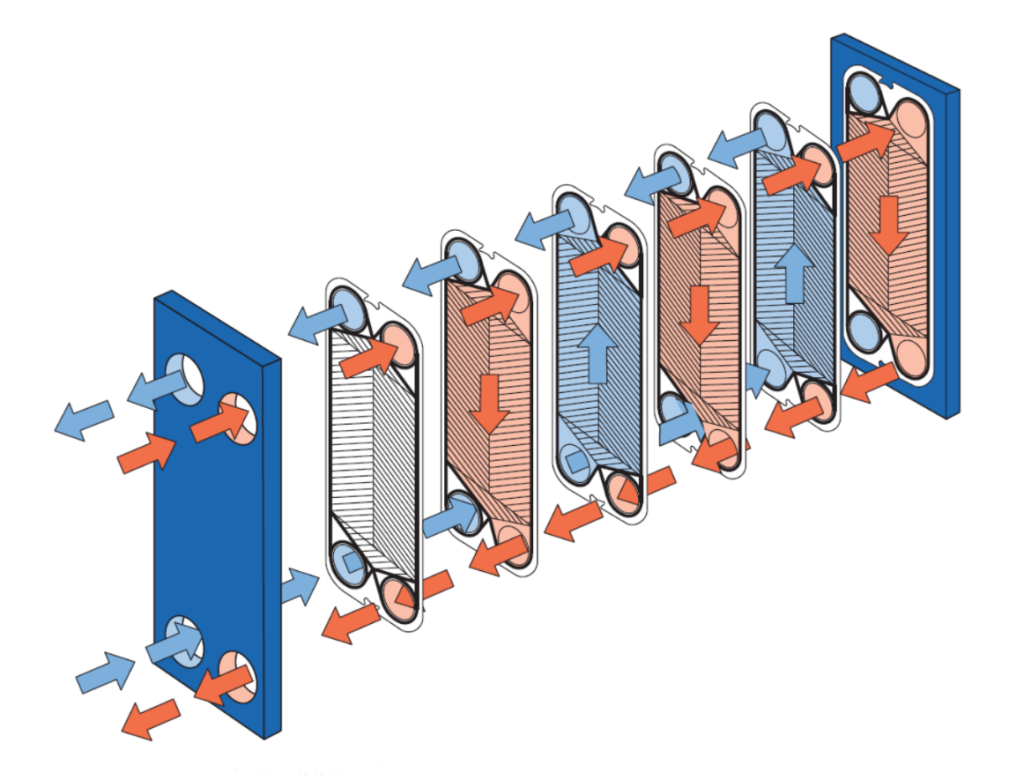

The fluid exchange principle of plate heat exchangers.

The world's first commercially viable Plate Heat Exchanger (PHE) was invented by Dr. Richard Seligman in 1923, revolutionizing the way fluids are indirectly heated and cooled. Dr. Richard Seligman founded APV (named after his initials) in 1910, originally a manufacturing company specializing in welded vessels for the brewing and vegetable oil industries. Simultaneously, it set the standard for thin metal plate heat exchangers, widely used worldwide today, through computer-designed configurations.

There are two different types of plate heat exchangers classified based on their structure and connection methods.

Combination Plate Heat Exchanger: This type combines the features of both gasketed plate heat exchangers and welded plate heat exchangers. In a combination plate heat exchanger, some plates are connected through gasketed seals, forming sealed channels suitable for medium to low pressure and temperature conditions. Meanwhile, other plates are connected through hard welding, creating more robust channels suitable for high-pressure and temperature conditions. This combination allows different working conditions in various areas of the same heat exchanger.

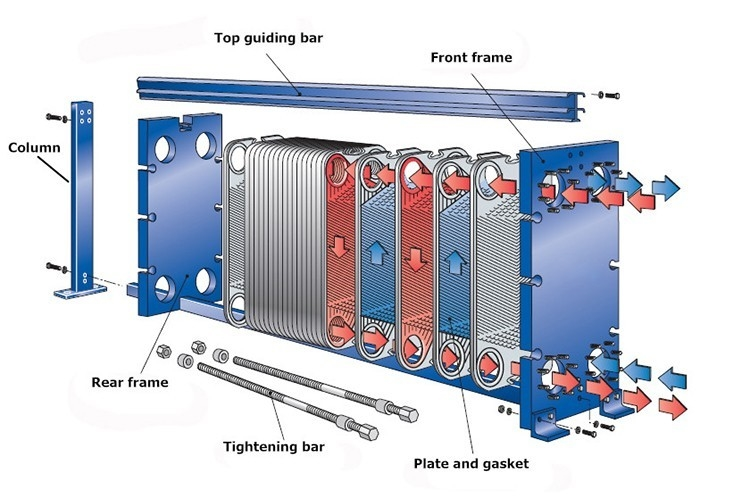

The structure of a combination plate heat exchanger.

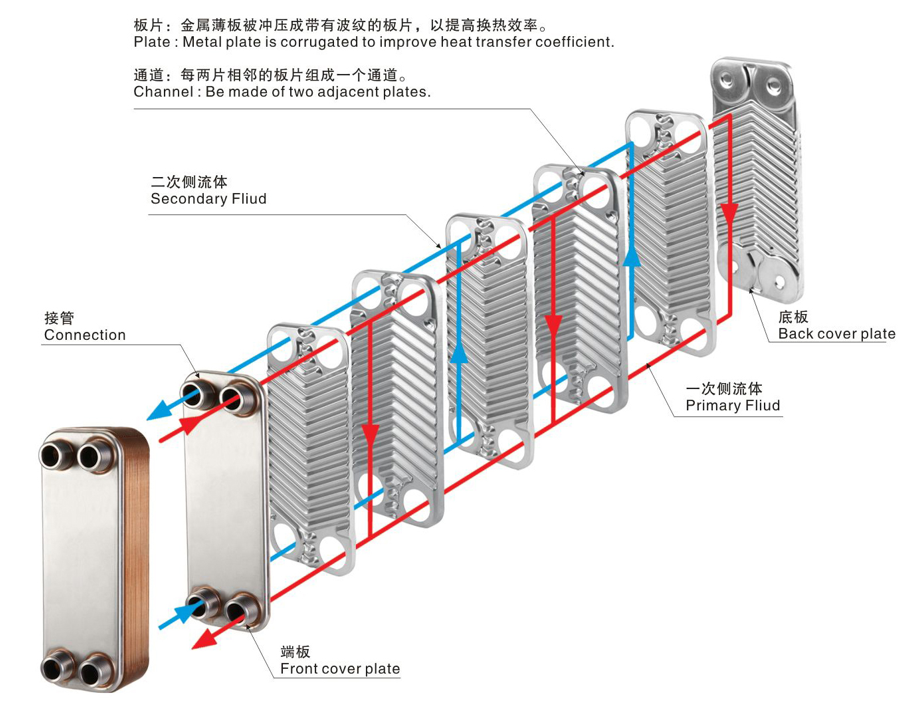

Welded Plate Heat Exchanger: In this type of heat exchanger, all metal plates are welded together to form sealed channels. Welded plate heat exchangers are suitable for extreme high-pressure and high-temperature conditions, offering higher resistance and durability.

Welded Plate Heat Exchanger Structure

Design of Plate Heat Exchangers

Plate Heat Exchangers (PHE) are specialized designs ideal for transferring heat between fluids at medium to low pressures. Welded, semi-welded, and cast plate heat exchangers are used for high-pressure fluid heat exchange or when more compact products are needed. The structure of a plate heat exchanger differs from a chamber traversed by pipes; instead, it consists of two alternating chambers, usually thin, separated by corrugated metal plates creating maximum surface area. The metal plates in plate heat exchangers are typically obtained through a one-time pressing process. Stainless steel is commonly used for the metal plates due to its high-temperature resistance, strength, and corrosion resistance.

The metal plates are separated by rubber sealing gaskets, adhered to a portion of the plate's edges. The plate heat exchanger's design channels the liquid flow through grooves pressed into the plates, oriented perpendicular to the fluid flow. These grooves are arranged to interconnect with grooves on other plates, forming channels, with gaps between plates measuring 1.3-1.5 mm. These plates are compressed together within a sturdy frame, creating parallel flow channels for alternating hot and cold fluids. These plates generate a large surface area, facilitating rapid heat transfer. Ensuring each chamber is thin guarantees most of the liquid volume contacts the plates, further enhancing heat exchange. The grooves also induce and maintain turbulence in the liquid, maximizing heat transfer. High turbulence can be achieved at low flow rates and high heat transfer coefficients.

Compared to shell-and-tube heat exchangers, plate heat exchangers can achieve temperature approaches (minimum difference between cold and hot fluid temperatures) as low as 1°C, whereas shell-and-tube heat exchangers require 5°C or more approach temperatures. Plate heat exchangers are smaller in size for the same heat transfer because the metal plates provide a large heat transfer area (the area through which heat can be transferred). Increasing or decreasing the heat transfer area in plate heat exchangers is simple, requiring adding or removing plates from the stack.

Evaluating Plate Heat Exchangers

All plate heat exchangers appear similar in appearance, with differences lying in the details of plate design and sealing technology. Therefore, when evaluating plate heat exchangers, it is essential to explore the product's specifics, analyze the manufacturer's level of research and development, and assess the availability of after-sales services and components.

An important factor to consider when evaluating heat exchangers is the form of internal corrugations. There are two types: intersecting corrugations and herringbone corrugations. Generally, herringbone corrugations are more commonly used as they can generate greater heat transfer enhancement for a given pressure drop compared to intersecting corrugations. There are numerous modification methods to improve the efficiency of heat exchangers, although it's challenging to ensure their support by commercial simulators. Additionally, some proprietary data may never be publicly available from heat transfer enhancement manufacturers. However, this does not imply that engineers cannot make predictive measurements of new technologies. Below are several contexts for different forms of heat exchanger improvements. The primary goal for cost-effective heat exchangers must always be achieved. Factors such as fouling capacity, reliability, and safety need to be considered.

Firstly, regular cleaning is essential. Periodic cleaning (on-site cleaning) is the most effective method to remove all waste and dirt that reduces the heat exchanger's efficiency over time. This method involves discharging both sides of the Plate Heat Exchanger (PHE) and isolating it from the fluid in the system. Rinse from both sides until the water becomes completely clear. For optimal results, flushing should be done in the opposite direction. After completion, circular pumps and solution tanks can be used to transmit cleaning agents, ensuring compatibility with the gaskets and plates of the PHE until the discharged flow is clear, followed by rinsing the system with water.

Optimization of Plate Heat Exchangers

To achieve improvements in Plate Heat Exchangers (PHE), two crucial factors must be considered: heat transfer rate and pressure drop. It is necessary to increase heat transfer while reducing pressure drop. In plate heat exchangers, the presence of corrugated metal plates results in significant resistance and high friction losses in the flow. Therefore, when designing plate heat exchangers, both these factors should be taken into account simultaneously.

For different ranges of Reynolds numbers, plate heat exchangers exhibit various correlations and herringbone angles. The geometric shape of the metal plates is one of the most significant factors affecting heat transfer and pressure drop in plate heat exchangers. However, this characteristic has not been precisely specified. In corrugated metal plate heat exchangers, the channels between the plates are narrow, leading to a high pressure capacity, and the flow becomes turbulent within these channels. Consequently, it requires more pumping power than other types of heat exchangers. Therefore, the goal is to achieve higher heat transfer and a smaller pressure drop. The shape of plate heat exchangers plays a vital role in industrial applications where pressure drop is a concern.

Flow Distribution and Heat Transfer Equations in Plate Heat Exchangers

The design calculations of plate heat exchangers involve flow distribution, pressure drop, and heat transfer. The former concerns how fluids are distributed within a piping system. The layout of plate heat exchangers can often be simplified into a system of two pipes that separate and combine fluids, categorized based on flow direction within the headers, such as U-type and Z-type arrangements, as illustrated in the header layout. Bassiouny and Martin previously developed design theories in this area. In recent years, Wang Jianyu (2008, "Pressure Drop and Fluid Distribution in Parallel Channels of Fuel Cell Stacks: U-Type Arrangement," International Journal of Hydrogen Energy) unified existing models and developed a comprehensive theory and design tool.

The total heat transfer rate between the hot and cold fluids can be expressed as: Q = UA∆Tm, where U is the overall heat transfer coefficient, A is the total plate area, and ∆Tm is the logarithmic mean temperature difference. U depends on the thermal conductivity of the fluids.

Cleaning can prevent fouling and scaling without the need to shut down the heat exchanger or interrupt operations. To avoid decreased heat exchanger performance and extended pipeline lifespans, online cleaning (OnC) can be used as a standalone method or combined with chemical treatments. Circulating ball systems and brush basket systems are examples of OnC techniques. Offline cleaning (OfC) is another effective cleaning method, significantly enhancing heat exchanger performance and reducing operational costs. This method, also known as pigging, involves a bullet-shaped device that can be inserted into each pipe and uses high air pressure to propel the device through the pipes. Methods like chemical cleaning, high-pressure washing, and hydro-blasting are widely used outside of OfC. When used strategically, these techniques can restore the heat exchanger to its optimal efficiency until fouling and scaling begin to gradually degrade the exchanger's efficiency.

Operational and maintenance costs are necessary for heat exchangers. However, there are various ways to reduce these costs. Firstly, costs can be reduced by minimizing fouling formation, which decreases the overall heat transfer coefficient. Estimated analyses indicate that fouling formation's impact results in substantial operational cost losses. The total fouling cost includes capital costs, energy costs, maintenance costs, and profit loss costs. Chemical fouling inhibitors are one method of fouling control. For instance, copolymers of acrylic acid/hydroxypropyl acrylic acid (AA/HPA) and acrylic acid/sulfonic acid (AA/SA) can be used to inhibit calcium phosphate deposition. Additionally, mounting the heat exchanger vertically can reduce fouling deposits as gravity pulls particles away from the heat conductive surface. Secondly, using saturated steam instead of superheated steam as the fluid can reduce operational costs. Superheated steam, acting as an insulator with poor thermal conductivity, is not suitable for heat applications like heat exchangers.

In summary, plate heat exchangers are highly efficient heat transfer devices widely applied in multiple fields. By optimizing the design, flow distribution, and heat transfer equations, higher heat transfer efficiency and lower pressure drops can be achieved. Regular cleaning and maintenance aid in maintaining the heat exchanger's performance, reducing operational costs, and prolonging its lifespan. Different corrugation patterns, materials, and configurations can be chosen to optimize plate heat exchanger performance for specific applications.